The Ultimate Guide to Laser Cutter CO2: Precision Engraving for Metal

Are you looking for a reliable and efficient way to engrave or cut metal? If so, the **laser cutter co2** might be the perfect tool for your needs. This innovative device has revolutionized the field of laser engraving, offering unparalleled precision and versatility. In this article, we’ll explore everything you need to know about the **metal laser engraving machine**, including its features, applications, and why it’s a must-have for professionals and hobbyists alike. Let’s dive in!

What is a Laser Cutter CO2?

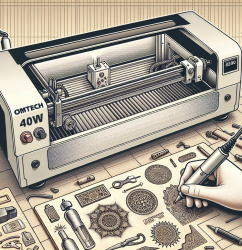

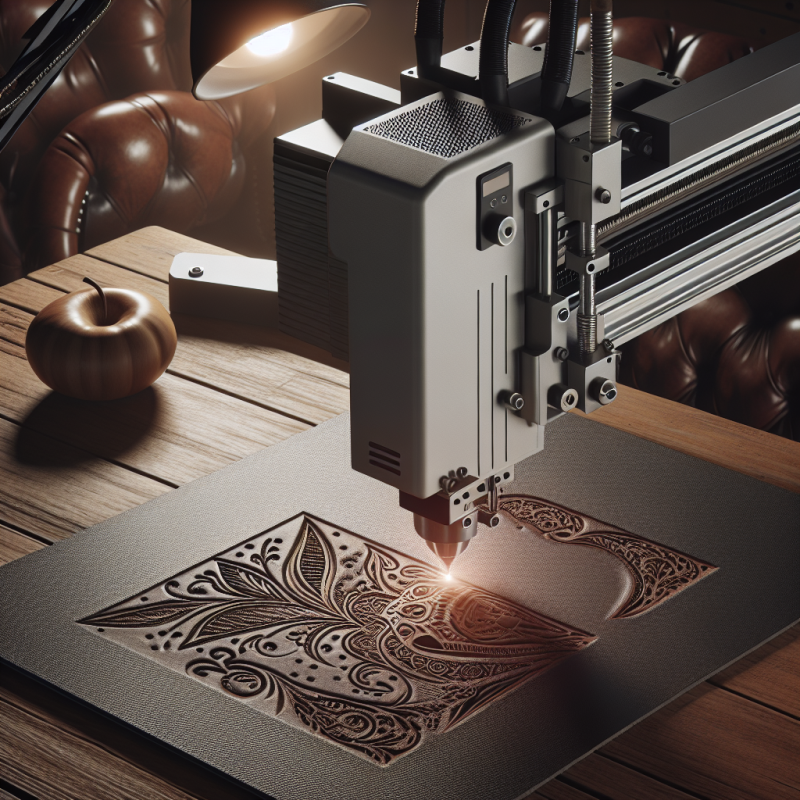

A **laser cutter co2** is a precision tool that uses a carbon dioxide laser to cut or engrave materials, with metal being one of its primary applications. Unlike traditional cutting methods, this machine operates with exceptional accuracy, making it ideal for intricate designs and patterns. The **laser engraver for metal** works by focusing a high-powered laser beam onto the surface of the material, vaporizing or melting it to create precise cuts or engravings.

One of the standout features of this machine is its ability to work with a wide range of materials, including stainless steel, aluminum, and other metals. This versatility makes it a popular choice for industries such as jewelry making, automotive repair, and custom metalwork. Whether you’re creating personalized engravings or cutting complex shapes, the **laser cutter co2** delivers consistent results every time.

How Does It Work?

The operation of a **laser cutter co2** is both fascinating and straightforward. The machine generates a laser beam by exciting carbon dioxide gas, which produces a high-energy light source. This light is then focused through a lens onto the surface of the material being cut or engraved. The intense heat from the laser causes the metal to melt or vaporize, creating clean and precise cuts.

One of the key advantages of this method is its non-contact nature. Unlike traditional cutting tools that physically interact with the material, the **laser engraver for metal** doesn’t require physical contact, reducing wear and tear on both the tool and the material. This also minimizes the risk of damaging delicate or intricate designs.

The machine can be controlled manually or via a computer interface, allowing users to input custom designs and patterns. This makes it highly adaptable to various projects, from small-scale engravings to large-scale industrial applications.

Key Features of the Metal Laser Engraving Machine

Now that we’ve covered the basics, let’s take a closer look at some of the **laser cutter co2**’s most impressive features:

- Precision and Accuracy: The machine delivers laser-cut edges with unparalleled precision, ensuring clean and professional results every time.

- Versatility: It works seamlessly with a variety of metal types, making it suitable for a wide range of applications.

- User-Friendly: The intuitive interface allows even beginners to operate the machine with ease.

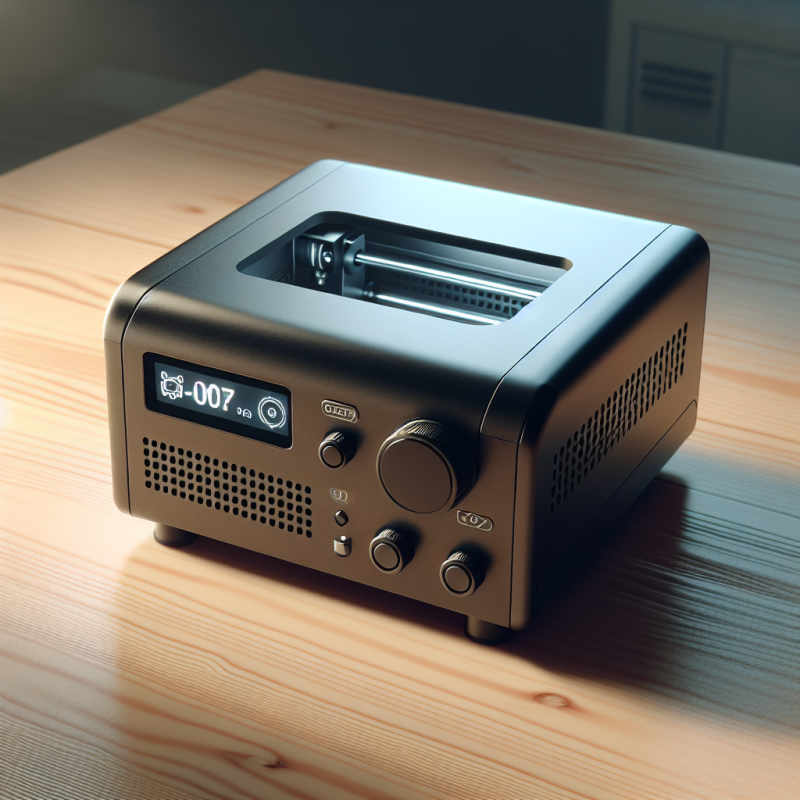

- Portability: Designed to be compact and lightweight, this machine is perfect for on-the-go projects or limited workspace environments.

These features make the **laser cutter co2** a versatile and indispensable tool for anyone working with metal. Whether you’re a professional craftsman or a hobbyist looking to take your projects to the next level, this machine has something for everyone.

Applications of the Laser Cutter CO2

The applications of the **laser cutter co2** are vast and varied. Here are some of the most common uses:

- Jewelry Making: Engrave intricate designs on rings, necklaces, and other jewelry pieces with ease.

- Metal Signage: Create custom signs with bold lettering or decorative patterns for businesses and homes.

- Automotive Repair: Use the machine to repair or customize parts of your vehicle, such as emblems or engine components.

- Crafts and Artwork: Transform metal into works of art by engraving detailed patterns or text.

These applications demonstrate the **laser cutter co2**’s ability to handle both small-scale and large-scale projects with equal precision. Its adaptability makes it a go-to tool for professionals across various industries.

Choosing the Right Laser Cutter CO2

If you’re in the market for a **laser cutter co2**, there are several factors to consider to ensure you choose the right one for your needs. Here are some questions to ask yourself:

- What type of projects do I plan to work on?

- How often will I use the machine?

- Do I need additional features, such as wireless connectivity or a built-in design library?

Answering these questions will help you narrow down your options and find the perfect machine for your needs. For example, if you’re primarily working on small-scale projects, a compact and portable model may be sufficient. However, if you plan to tackle larger or more complex designs, you’ll want to invest in a heavier-duty machine with advanced features.

Maintenance and Safety Tips

Like any precision tool, the **laser cutter co2** requires proper maintenance to ensure optimal performance. Here are some tips to keep your machine running smoothly:

- Clean Regularly: Dust and debris can accumulate on the machine’s surfaces, so make sure to clean it regularly.

- Check the Laser Tube: Inspect the laser tube for any signs of wear or damage, as this is a critical component of the machine.

- Follow Safety Guidelines: Always wear protective eyewear when operating the machine and ensure it’s placed in a well-ventilated area to avoid inhaling fumes from the cutting process.

By following these maintenance and safety tips, you can extend the lifespan of your **laser cutter co2** and ensure safe and efficient operation for years to come.

Why Invest in a Laser Cutter CO2?

If you’re still on the fence about whether to invest in a **laser cutter co2**, here are some compelling reasons why it’s worth considering:

- Enhanced Precision: Achieve cleaner cuts and more detailed engravings compared to traditional methods.

- Time-Saving: The machine operates at high speeds, reducing the time required for even complex projects.

- Cost-Effective: While the initial investment may seem significant, the machine’s versatility and long lifespan make it a cost-effective choice in the long run.

These benefits highlight why the **laser cutter co2** has become an essential tool for professionals and hobbyists alike. Whether you’re looking to start a new business or enhance your current projects, this machine offers unparalleled value and performance.

Conclusion

The **laser cutter co2** is more than just a tool—it’s a game-changer for anyone working with metal. Its precision, versatility, and ease of use make it an indispensable addition to any workshop or studio. Whether you’re creating custom jewelry, signage, or intricate artwork, this machine delivers exceptional results every time.

If you’re ready to take your metalworking projects to the next level, consider investing in a **laser cutter co2** today. With its numerous benefits and adaptability, it’s sure to become one of your most trusted tools for years to come. So why wait? Start exploring the possibilities of laser cutting and engraving with this incredible machine!

If you’re interested in learning more or purchasing a **laser cutter co2**, visit today!