“

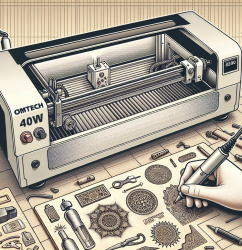

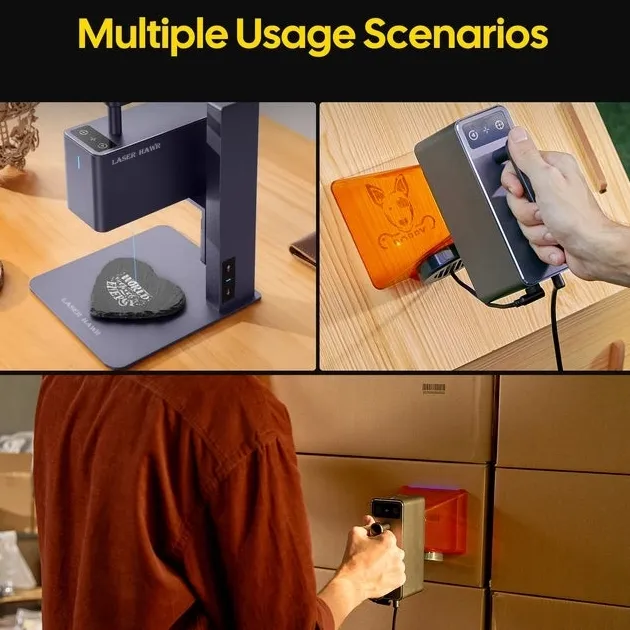

Introducing the LaserHawk LH2, a cutting-edge laser engraving machine designed to redefine precision and versatility in the world of laser technology. Whether you’re a professional craftsman, a small business owner, or a DIY enthusiast, the LaserHawk LH2 is your ultimate tool for creating intricate designs, personalized engravings, and precise cuts on a variety of materials.

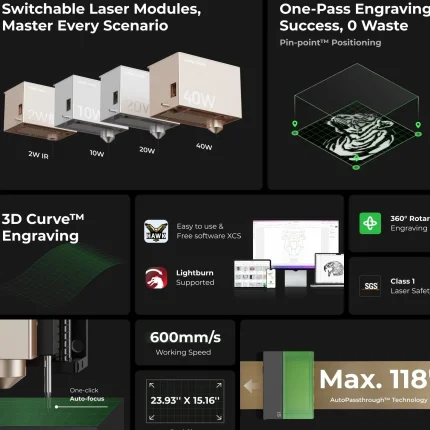

This maverick 88 laser engrave machine stands out with its advanced features and user-friendly design, making it the perfect choice for both beginners and experts. With its powerful engraving laser, the LaserHawk LH2 delivers unmatched accuracy and speed, ensuring flawless results every time.

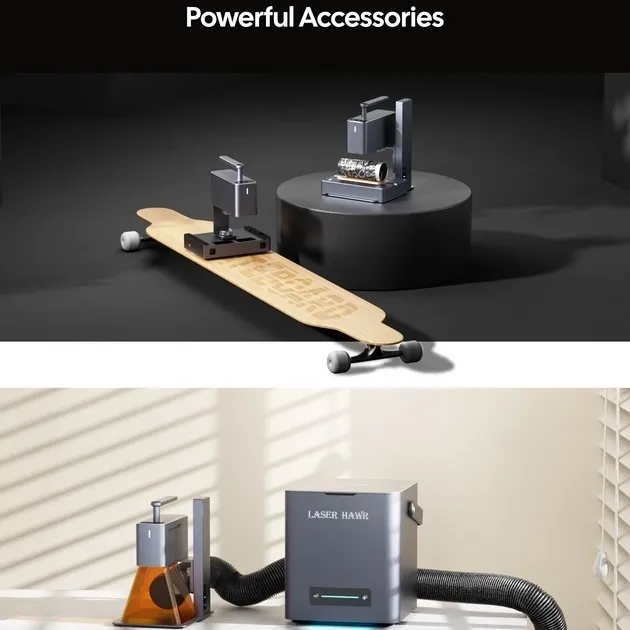

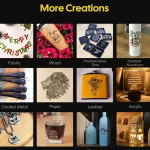

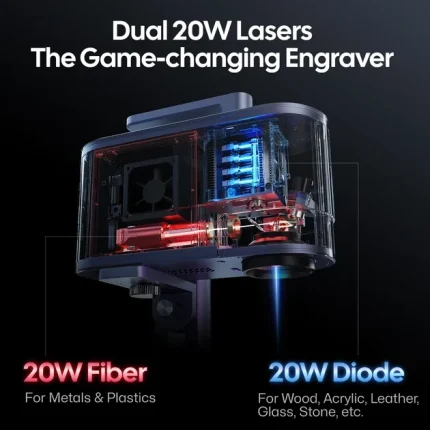

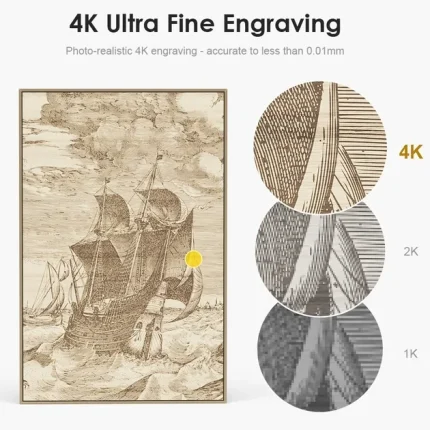

- High-Precision Engraving: The LaserHawk LH2 is equipped with a state-of-the-art metal laser engraver that can etch detailed designs on metals, wood, acrylic, glass, and more. Its precision is unmatched, making it ideal for intricate projects.

- Versatile Cutting Capabilities: Not just an engraver, this machine doubles as a powerful laser cutter, capable of slicing through materials with ease. From custom signage to intricate stencils, the possibilities are endless.

- User-Friendly Interface: Designed with simplicity in mind, the LaserHawk LH2 features an intuitive control panel and easy-to-use software, allowing you to start your projects in minutes.

- Durable and Reliable: Built with high-quality components, this machine is designed to withstand heavy use, ensuring long-lasting performance and reliability.

- Compact and Portable: Despite its powerful capabilities, the LaserHawk LH2 is compact and lightweight, making it easy to transport and set up in any workspace.

Whether you’re engraving a maverick 88 laser engrave design on a firearm, creating custom jewelry with a metal laser engraver, or crafting personalized gifts with an engraving laser, the LaserHawk LH2 is the ultimate tool to bring your creative visions to life. Experience the future of laser technology today with the LaserHawk LH2 – where precision meets innovation.

More you like:

Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | Xtool laser engraver ✔Laser engraver machine ✔Hawk F1 IR+DIODE | Laser engraving✓Laser cutter machine✓Laser engraver engraving machine✓LaserHawk LH2 | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Laser engraver machine✓ Fiber laser engraver✓Laser engraver for metal✓LaserHawk LH3 | Laser for engraving machine✔ Laser engraver for wood✔ Hawk P2S CO2 cutter laser | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series | Xtool laser engraver ✔Laser engraver machine ✔Hawk F1 IR+DIODE | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series

Wei Kim –

As a laser engraver user, I give this machine 5 stars! The engravings are crisp & precise. The operation is smooth, software intuitive. Fast speeds boost productivity. Sturdy build, reliable performance!

Otto Young (verified owner) –

**Performance & User Experience Review:**

The xTool F1 diode laser excels in precision (0.01mm) across materials: birch plywood etches cleanly at 1000mm/min/60% power, while cast acrylic retains sharp edges. Leather engraves uniformly without scorching. However, the 12×8″ bed limits large projects. Setup is intuitive—30-minute assembly—but crosshair alignment requires manual tweaking. XCS software offers material presets, though advanced users may crave manual control for niche materials like anodized aluminum. The rotary attachment (included) handles tumblers flawlessly. A stellar midrange choice, but workspace expansion or granular power settings would elevate versatility.

Alexei Dubois (verified owner) –

**Laser Engraver Review for Architectural Model Making**

1. **Specific Project Experience:**

– **Educational Materials:** Utilized the laser engraver on acrylic to create detailed architectural models and plaques, enhancing visual communication of designs.

– **Material Behavior & Results:** Acrylic responded well to laser engraving, offering crisp details. However, managing fumes was a challenge.

– **Challenges & Solutions:** Addressed fume issues with improved ventilation and adjusted power settings for consistent depth across layers.

2. **Business/Creative Impact:**

– **Workflow Efficiency:** The tool significantly reduced manual labor, speeding up production and allowing more intricate designs.

– **Customer Feedback:** Clients appreciated the precision and detail, leading to repeat business and referrals.

– **Return on Investment:** Achieved positive ROI within months due to increased demand and efficiency gains.

This laser engraver has proven invaluable in enhancing both creativity and business operations, making it a cornerstone of our model-making process.

Anders Dubois –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation boost workflow. Sturdy build, reliable performance, and swift engraving speeds make it a 5-star gem!”