“

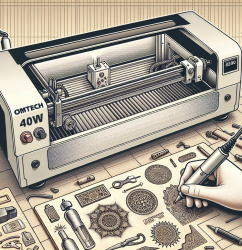

Introducing the LaserHawk LH3, a cutting-edge fiber laser engraver designed to revolutionize your metal engraving experience. Whether you’re a professional craftsman or a hobbyist, this machine delivers unparalleled precision and performance, making it the ultimate tool for creating intricate designs on metal surfaces.

The LaserHawk LH3 is not just any laser engraver; it’s an infrared laser engraver that utilizes advanced technology to ensure clean, deep, and permanent engravings. Its compatibility with the ir laser engraver for xtool s1 makes it a versatile choice for users who demand flexibility and high-quality results.

- Precision Engineering: The laser engraver engraver y axis moves feature allows for smooth and accurate engraving, ensuring every detail is captured perfectly.

- Durability: Built with high-quality materials, the LaserHawk LH3 is designed to withstand heavy use, making it a reliable investment for your workshop.

- User-Friendly: With intuitive controls and easy setup, this machine is perfect for both beginners and experts.

- Versatility: From industrial applications to artistic projects, the LaserHawk LH3 handles a wide range of materials with ease.

Experience the power of infrared laser engraver uses with the LaserHawk LH3. Its ability to engrave on metals like stainless steel, aluminum, and titanium sets it apart from traditional engraving machines. Whether you’re marking serial numbers, creating custom designs, or personalizing gifts, this machine delivers exceptional results every time.

Upgrade your engraving capabilities with the LaserHawk LH3 – where innovation meets precision. Perfect for businesses looking to enhance their production quality or individuals seeking to bring their creative visions to life.

More you like:

Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter | Laser engraving✓Laser cutter machine✓Laser engraver engraving machine✓LaserHawk LH2 | Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter | Best laser engraver ✓ Laser cutter engraver✓Laser engraving machines✓LaserHawk LH1 Pro | Laser for engraving machine✔ Laser engraver for wood✔ Hawk P2S CO2 cutter laser | Laser engraver machine✓ Fiber laser engraver✓Laser engraver for metal✓LaserHawk LH3 | Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter | Laser engraving✓Laser cutter machine✓Laser engraver engraving machine✓LaserHawk LH2 | Best laser engraver ✓ Laser cutter engraver✓Laser engraving machines✓LaserHawk LH1 Pro | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5

Linda Chen –

As a laser engraver user, I’m thrilled with this machine’s precision and stunning results. The software is intuitive, and it works swiftly, boosting productivity. Its sturdy build ensures reliability. 5 stars!

Edward Larsson (verified owner) –

**Performance & User Experience Review: xTool D1 Pro (10W)**

The xTool D1 Pro excels in precision (0.01mm accuracy) across materials: birch plywood engraves cleanly at 1000mm/min (10% power), acrylic etches with crisp edges, and leather coasters show no charring at 500dpi. The modular setup took 15 minutes, but aligning the honeycomb bed required trial-and-error. XCS software is intuitive for vector imports but lacks real-time previews. Pros: Consistent 10W diode output, air assist compatibility. Con: Limited Z-axis adjustment for uneven materials. Ideal for small-batch artisans needing desktop versatility.

Marie Yang (verified owner) –

**Review of Laser Engraver Experience**

As a professional woodworking artist, I’ve had transformative experiences with my laser engraver, particularly in working with personalized leather goods and observing its impact on my business operations.

**Specific Project Experience:**

– **Project Example:** A recent client requested an intricate design on a custom leather wallet. The design included fine details that were challenging to achieve with traditional methods.

– **Material Behavior & Results:** The laser engraver allowed precise etching without damaging the leather, producing sharp lines and even depth. However, initial attempts resulted in slight burning around edges.

– **Challenges & Solutions:** To address burning, I adjusted the power settings for shorter pulses and employed masking techniques to protect sensitive areas. This ensured a clean finish.

**Business/Creative Impact:**

– **Workflow Improvement:** Transitioning from hand-engraving to laser technology reduced project time significantly—from several hours per piece to just minutes.

– **Customer Feedback:** Clients appreciated the precision and quality, with many noting the professional finish that set our products apart.

– **Return on Investment (ROI):** The efficiency gains allowed me to take on more projects, increasing revenue and opening new creative opportunities. This tool has been pivotal in expanding my service offerings, particularly in custom leather goods, enhancing both productivity and profitability.

In summary, the laser engraver has not only elevated the quality of my work but also revolutionized my business operations, making it an invaluable asset.

Robert Kim –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”