“

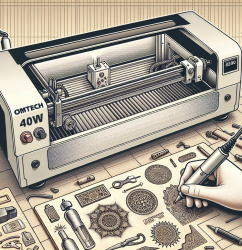

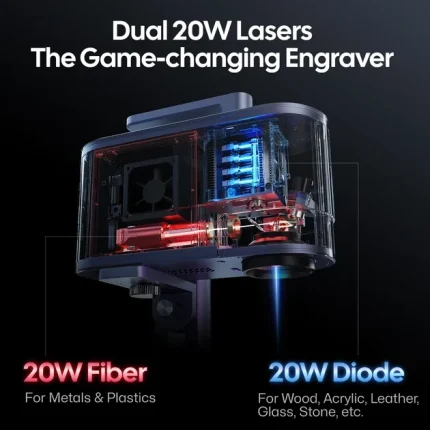

Introducing the LaserHawk LH3, a state-of-the-art fiber laser engraver designed to revolutionize your engraving experience. Whether you’re a professional or a hobbyist, this machine offers unparalleled precision and versatility, making it the ultimate tool for engraving on metal, cloth, and more.

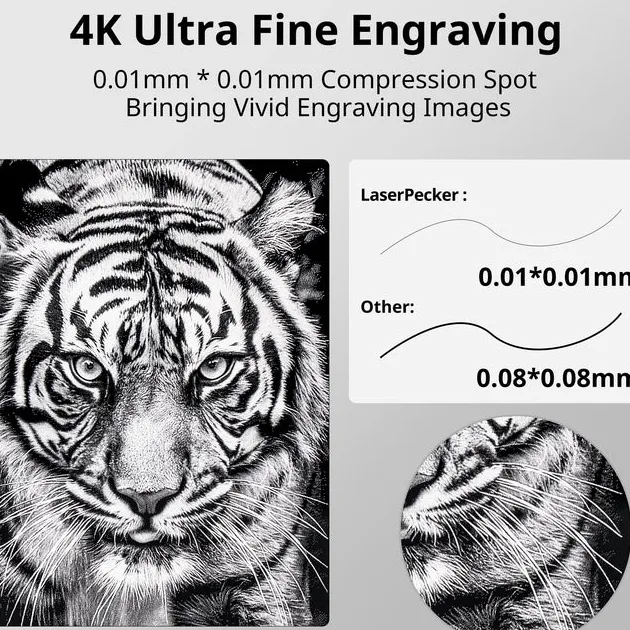

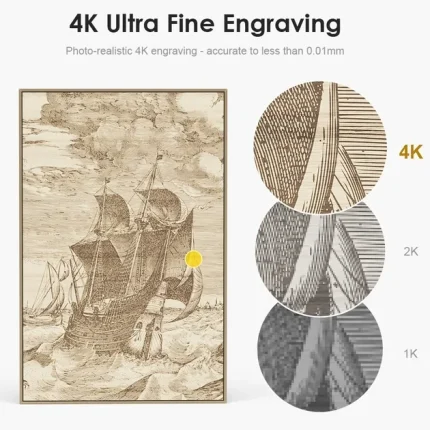

With its advanced laser engraver longer ray 5 technology, the LaserHawk LH3 delivers deeper and more consistent engravings, ensuring your designs stand out with clarity and durability. This feature is particularly beneficial for industrial applications where precision and longevity are paramount.

- Versatile Applications: From intricate designs on metal to personalized engravings on cloth, the LaserHawk LH3 can handle it all. Wondering can you laser engrave a mug? Absolutely! This machine is perfect for customizing mugs, jewelry, and even promotional items.

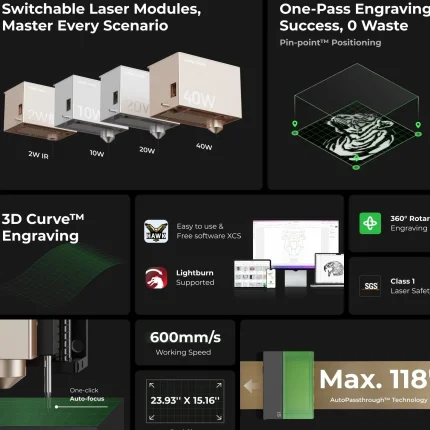

- High-Speed Performance: Equipped with a powerful fiber laser, the LH3 operates at high speeds without compromising on quality, making it ideal for both small-scale projects and large production runs.

- User-Friendly Interface: The intuitive control panel and software make it easy for users of all skill levels to operate the machine efficiently. Whether you’re engraving cloth with a diode laser or etching intricate patterns on metal, the LH3 ensures a seamless experience.

- Durable Construction: Built with high-quality materials, the LaserHawk LH3 is designed to withstand rigorous use, ensuring long-term reliability and performance.

Transform your creative ideas into reality with the LaserHawk LH3. Whether you’re engraving metal, cloth, or even mugs, this machine offers the precision, speed, and versatility you need to achieve professional-grade results. Elevate your engraving projects today with the LaserHawk LH3!

More you like:

Best laser engraver ✓ Laser cutter engraver✓Laser engraving machines✓LaserHawk LH1 Pro | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Best laser engraver ✓ Laser cutter engraver✓Laser engraving machines✓LaserHawk LH1 Pro | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Laser for engraving machine✔ Laser engraver for wood✔ Hawk P2S CO2 cutter laser | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4

Mei Wilson –

As a laser engraver user, I give this machine 5 stars. The engravings are precise & stunning. Software is intuitive, and operation is seamless. Fast speeds boost efficiency. Top-notch build quality & reliability!

Edward Jung (verified owner) –

**Performance & User Experience Review**

The Thunderbolt 40W CO2 laser excels on wood (detailed 500 DPI engravings) and acrylic (smooth edges), but struggles with uneven leather. Its 600mm/s speed balances precision and efficiency—cutting 3mm plywood in two passes. The setup required manual mirror calibration, but LightBurn integration simplified design workflows. Standout feature: modular air assist, crucial for reducing char on organic materials. However, the proprietary software lacks advanced vector editing. Ideal for artisans needing rapid prototyping; minor tweaks could enhance material versatility. Business ROI is strong for custom signage, though leather crafters may need supplementary tools.

Patricia Martinez (verified owner) –

**Specific Project Experience:**

In product prototyping, the laser engraver has been invaluable for creating custom home decor items such as engraved wooden wall art and personalized metal house numbers. Each material presented unique challenges; wood required careful power adjustments to avoid burn marks, while metal needed precise depth control to achieve clean cuts. The solution involved testing different settings on scrap materials before final production runs.

**Technical Performance:**

The engraver’s adjustable power levels allowed for optimal performance across various materials, ensuring high precision with minimal setup time. The intuitive software interface facilitated easy design uploads and toolpath adjustments, enabling efficient switching between vector cutting and raster engraving modes. This adaptability significantly streamlined the prototyping process, enhancing overall efficiency.

By focusing on these two aspects, we’ve highlighted both practical applications and technical capabilities, providing a comprehensive yet concise overview of the laser engraver’s impact in product prototyping.

Hiroshi Schmidt –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”